Packaging is essential to maintaining product safety, effectiveness, and market appeal in today’s cutthroat manufacturing environment. More and more companies are switching from antiquated manual processes to cutting-edge automated solutions like those provided by G-Tech Packaging. Let’s examine the differences between these two strategies and the reasons automation is increasingly being chosen.

Conventional Packaging Techniques

Conventional packaging techniques mostly use semi-automated equipment or manual labor. Although short-term cost-effective, these approaches frequently have drawbacks like:

- Labor Dependency: Production is slowed down by a heavy reliance on labor.

- Inconsistency: Human error-related variations in labeling, filling, and sealing.

- Limited Speed: High-volume industrial demands cannot be met by manual packaging.

- Increased Contamination Risk: Inaccuracy can lower the quality of products, particularly in the food, drink, and pharmaceutical industries.

- Traditional approaches restrict scalability and efficiency, even though they might still be effective for small businesses.

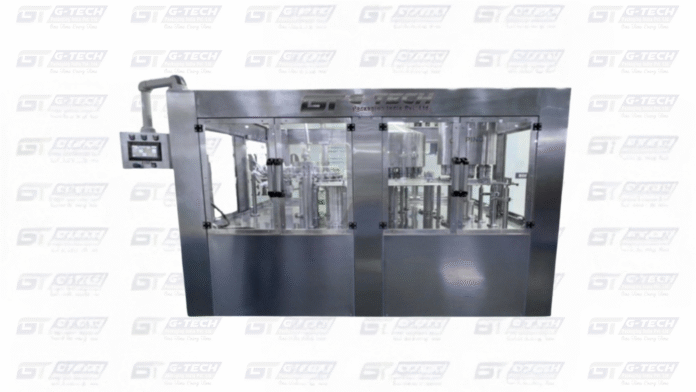

G-Tech Packaging Equipment: The Contemporary Benefit

Packaging by G-Tech Advanced automation is built into machines to address the drawbacks of manual processes. They offer several benefits, such as:

- High-Speed Production: Filling, capping, and labeling systems are examples of machines that guarantee quicker output with less downtime.

- Accuracy and Consistency: PLC-based controls ensure that each batch is filled, sealed, and labeled consistently.

- Cost Efficiency: Although they require a larger initial investment, they are ultimately more cost-effective due to lower labor expenses and less waste.

- Hygiene and Safety: Strict industry standards are met by contactless operations, which improve product safety.

- Scalability: Equipment can be tailored for sectors such as pharmaceuticals, lubricants, food, and beverages.

The Transition to Automation

Businesses can no longer rely only on manual packaging due to the increasing demand. Modern equipment from G-Tech Packaging maximizes productivity while guaranteeing quality and adherence to regulations. Businesses can future-proof their operations and satisfy present market demands by investing in automated solutions.

In conclusion

Even though conventional packaging techniques have been used by industries for many years, they are no longer adequate for the large-scale demands of today. With their speed, accuracy, hygienic features, and scalability, G-Tech Packaging Machines are the more sensible and environmentally friendly option for companies looking to maintain their competitive edge in the market today.