By 2026, automation will have taken center stage in the rapidly changing global edible oil market. Manufacturers are being forced to implement sophisticated automatic filling, capping, and labeling systems due to the growing demand for palm, soybean, and sunflower oils. These devices minimize waste and human error by ensuring accuracy, cleanliness, and efficiency. Faster production and consistent quality are made possible by servo and PLC-based technologies. A new era of dependability and innovation is being ushered in by automated edible oil lines from businesses like G-TECH Packaging, where each drop is precisely packed to satisfy future market demands and international standards as sustainability and smart manufacturing gain importance.

Shifting Market Conditions

By 2026, it is anticipated that the global edible oil market will have undergone substantial change due to factors like population expansion, growing health consciousness, and rising processed food consumption. The demand for sunflower, soybean, palm, and mustard oils is steadily increasing in nations throughout Asia, the Middle East, and Africa. In order to satisfy the demands of the global supply chain, this surge forces manufacturers to implement quicker, more intelligent, and more effective packaging solutions.

Automation’s Place in the New Era

Automation is now a need rather than a luxury. Automatic edible oil filling lines with PLC control systems and servo-based technology guarantee flawless bottle-to-bottle accuracy, high speed, and little waste. Filling, capping, labeling, and sealing are among the tasks that these systems manage, resulting in a smooth production flow with less human involvement.

Fundamental Accuracy and Sanitation

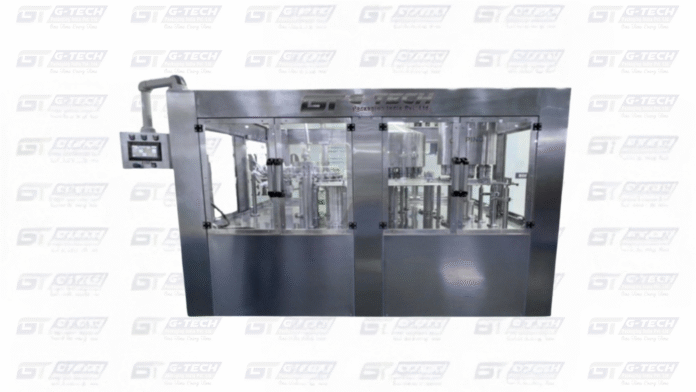

The standards for edible oil packaging are being redefined by automatic machines. The sophisticated filling and capping systems from G-TECH Packaging guarantee contactless operation, constant volume control, and product hygiene. Efficiency and adherence to international food safety and quality standards are the outcomes.

Eco-Friendliness and Intelligent Production

Automated systems minimize energy use, minimize oil spills, and maximize the use of packaging materials as sustainability becomes increasingly important in international trade. In line with the “Industry 4.0” vision, integration with smart sensors and IoT-based monitoring guarantees predictive maintenance and real-time efficiency tracking.

Prospects for 2026

Automation will rule the edible oil market by 2026, affecting both domestic producers and foreign exporters. High-performance automatic edible oil filling lines that enable industries to maintain their competitiveness and global compliance are the contribution of G-TECH.