The lubricant industry demands strength, precision, and consistency at every stage of packaging. From engine oils and industrial lubricants to greases and specialty fluids, manufacturers need machines that can handle high viscosity, prevent leakage, and ensure exact filling. This is where GTECH has emerged as a trusted and preferred partner for the lubricant industry.

Expertise in Handling High-Viscosity Products

Lubricants are thicker and more challenging to fill than regular liquids. GTECH designs its machines specifically to handle high-viscosity products without spillage, air pockets, or inconsistency. Advanced piston and servo-based filling systems ensure smooth flow and uniform filling, even for heavy oils and greases.

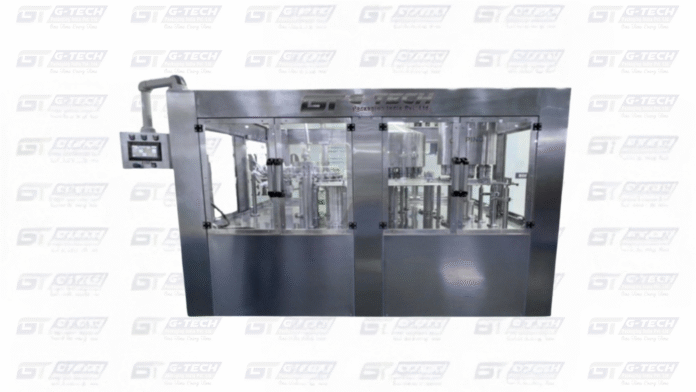

Strong, Durable & Industrial-Grade Design

Lubricant packaging requires machines that can withstand tough industrial environments. GTECH machines are built with robust construction, high-quality components, and long-lasting materials. This durability ensures continuous operation with minimal breakdowns, making them ideal for large-scale lubricant production units.

High Accuracy with Zero Wastage

Accuracy plays a major role in lubricant packaging, as product loss directly impacts cost. GTECH machines offer precise volume control, ensuring every bottle, jar, or drum is filled accurately. Consistent output not only reduces wastage but also maintains brand credibility in competitive markets.

Leak-Proof & Clean Packaging

Leakage is one of the biggest concerns in lubricant packaging. GTECH integrates leak-proof nozzles, controlled filling mechanisms, and secure capping systems to eliminate spillage. This results in clean bottles, safe transportation, and a professional final product that meets industry standards.

Complete Lubricant Packaging Line

GTECH provides end-to-end packaging solutions for the lubricant industry. Filling, capping, induction sealing, labeling, and secondary packaging can all be integrated into a single automated line. This improves efficiency, reduces manpower dependency, and increases production speed.

Customization for Different Lubricant Applications

Whether it’s small automotive oil bottles, large industrial containers, or customized packaging formats, GTECH offers flexible solutions. Machines can be customized based on filling range, container size, automation level, and production capacity, making them suitable for startups as well as established lubricant brands.

Strong After-Sales Support & Long-Term Partnership

GTECH is known not just for its machines, but also for its dependable after-sales support. Quick service response, technical assistance, and availability of spare parts ensure smooth and uninterrupted operations for lubricant manufacturers.

Conclusion: A Smart Choice for the Lubricant Industry

With precision engineering, rugged design, accurate filling, and complete automation solutions, GTECH stands out as one of the best choices for the lubricant industry. For manufacturers aiming for efficiency, consistency, and long-term growth, GTECH delivers reliability you can trust.