Special features

- Detects micro holes with high repeatability

- Stores up to 10 different test parameters, adjustable during operation

- Easy height adjustment with a single hand wheel

- Reflector-less photocell for fast and accurate bottle positioning

- Festo and imported brand valves and cylinders for reliability

- Imported pressure sensor for precise and consistent leak measurement

- Delta make PLC with 2 x 16 character LCD display for user-friendly control

- Integrated 5-digit pass and fail counters for easy tracking

- Variable speed drive with linear acceleration and deceleration control

- Capable of detecting holes as small as 0.25 mm

- Compatible with most bottle types and sizes

Testing capacity (approx.)

- Less than 0.25 liters: Up to 3000 bottles/hour

- 0.5 to 1 liter: 1200–1400 bottles/hour

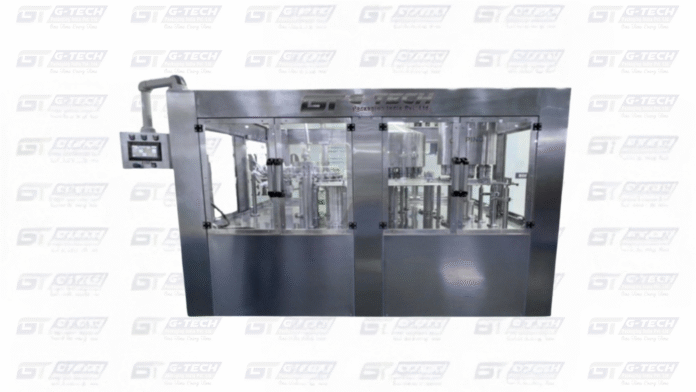

Jar Leak Detector Machine – Product description

The Jar Leak Detector Machine by G-Tech is an advanced and high-speed solution for detecting micro leaks in plastic bottles and jars with exceptional precision. Built with imported components and Delta PLC control, it ensures reliable, repeatable leak detection even at high production speeds.

Capable of identifying holes as small as 0.25 mm, this machine is equipped with a precision pressure sensor, Festo-brand pneumatic components, and a reflector-less photocell for fast bottle positioning. The system supports up to 10 programmable test parameters, allowing the operator to switch easily between bottle types without manual reconfiguration.

Its variable speed drive ensures smooth movement with linear acceleration/deceleration, reducing bottle instability during testing. The 5-digit pass/fail counters, LCD display, and single-hand height adjustment make it extremely user-friendly for operators on a busy production line.

Whether you’re testing bottles under 250 ml at up to 3000 per hour or handling 1-liter containers at 1400 per hour, G-Tech’s Jar Leak Detector Machine offers unmatched quality control to help protect your product integrity.

Get a Free Quote Today

Request customised filling and packaging solutions for your business today.

Request a Quote